System Control & Visualization with Schröter Systems

Intelligent control for efficient processes

Intelligent control is essential for the efficiency and process reliability of industrial systems. Schröter uses tried-and-tested PLC control systems from Siemens on the European market and worldwide. For the Japanese market, automation solutions from Mitsubishi systems with Japanese typesetting are used, while Allen Bradley controllers are used in the USA. The control system is currently available in 29 languages and is easy to operate via a user-friendly touch panel.

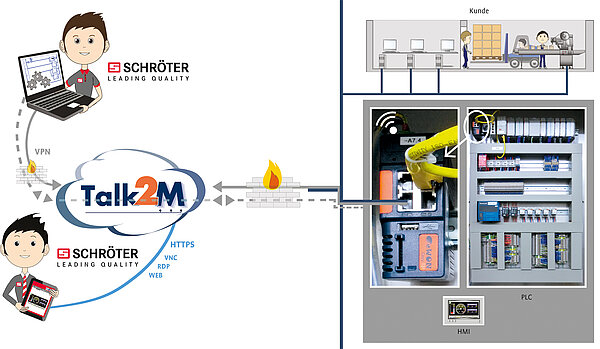

Digital networking and remote maintenance

All control systems are designed for secure remote maintenance, which is carried out via an eWon security router from Wachendorff Prozesstechnik. This means that systems can be supported, analyzed, and optimized worldwide without having to be on site. This reduces maintenance costs, increases operational reliability, and minimizes downtimes.

Process visualization for maximum transparency

The optional process visualization offers a detailed display of all production processes in real time. Temperature curves, humidity values, and process steps can be monitored and documented directly. This allows users to react immediately to deviations and control their production processes efficiently. The visualization is intuitive to use and can be adapted to individual requirements.

Summary of advantages

- Maximum efficiency and operational reliability thanks to intelligent control systems

- Various PLC control systems available with technology adapted to the market

- 29 languages available for intuitive operation

- Secure remote maintenance via eWon router for worldwide monitoring

- Optional process visualization for detailed real-time control

Variants