THERMICjet®

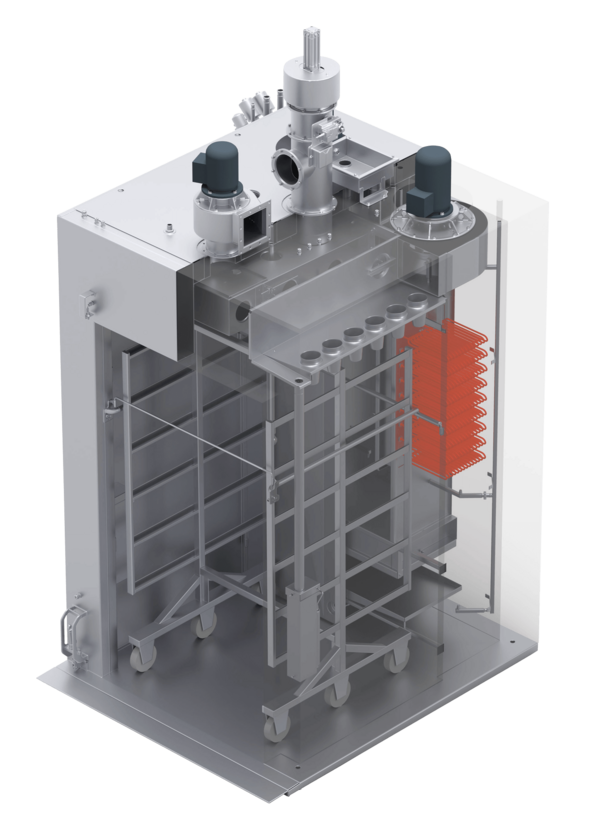

The THERMICjet® system is the ideal solution for steaming, boiling, smoking, cooking, and drying food. Thanks to standardized processes and a uniform design, it ensures consistently high product quality and reliable production. Whether single-row or double-row system, for all sizes and shapes of transport wagons – the THERMICjet® meets the highest standards of efficiency and precision.

Applications

Key facts about THERMICjet® at a glance

Application areas

- HR: Roasting, drying, hot smoking, cooking, steaming

- KA: Steaming, cooking

- HL: Roasting, drying, cooking, boiling

- WR: Warm smoking, drying

- TR: Drying

- KK: Cooking, boiling, blanching

- PA: Pasteurizing, cooking

- OPTIONAL: Cold smoking, air cooling, shower cooling, baking

System concept

- Single-row or double-row systems

- Transit (flow-through) version possible

Transport unit

- Rolling wagons

- Transport racks

- Stacking modules

- Overhead conveyors/hanging racks

Temperature range

- Depending on the process up to 110 °C (baking up to 180 °C)

Automatic inspection display

Remote maintenance

- Online access possible

Process data management

- Integration into central process control software

The most important features

- Customized loading systems for transport wagons, floor racks and overhead rail systems

- A high-temperature baking system can be included

- A cooling coil can be integrated for fermentation and cold-smoke processes

- Supports digital optimization through remote access and data analysis

High-performance hot smoking and cooking systems

Our THERMICjet® sets standards in food processing and combines all essential processes in one system: boiling, steaming, smoking, cooking, roasting, drying and shower cooling. Thanks to its design and optional add-ons, such as a baking system or cooling coil, the THERMICjet® adapts perfectly to individual production requirements. With a choice of door systems – from the standard swing door to the lifting door – the system is a versatile solution for both industrial and artisanal customers.

Outstanding process solutions with hot air and hot smoke cooking systems for Industry

The THERMICjet® is available in two main versions: as a hot-smoke cooking system (HR) and as a pure steam cooking system (KA). Both variants impress with their precise control, high energy efficiency, and precisely repeatable processes. The system design and manufacturing quality guarantee the highest standards of hygiene.

Both industrial and artisanal customers benefit from our highly developed THERMICjet® systems. Whether large-scale industrial systems or compact single-wagon units – the versatile design and flexible combination options offer customized solutions to suit every requirement.

THERMICjet® cooking kettle systems impress with their steam and air-tight design, which ensures maximum efficiency and product safety. They can be heated using low / high-pressure saturated steam, which is blown into the heating jacket on several sides to ensure precise temperature distribution. The resulting condensate is returned to the steam generator via a steam trap and a collecting pipe. A cooking kettle can also be heated electrically or with gas, with a choice of direct or indirect heating with thermal oil.

Features for maximum efficiency with smoking and cooking systems

Thanks to vertical air circulation with alternating air flow and flexible loading systems, the THERMICjet® processes both large and small batches – depending on the size of the system – evenly and efficiently. Interval showers ensure initial cooling of the products and integrated cleaning systems provide for maximum operational safety and hygiene.

In order to prolong the shelf life of products, Schröter offers pasteurization systems that are characterized by a particularly product-friendly pasteurization principle. They are ideal for specialties such as brown bread, salmon roe, or meat products. The products are ideally thermally treated in heat-resistant containers stacked on EUR pallets. The pasteurization process works with low-pressure steam, which heats the interior of the system to around 100 °C at a pressure of 140 mbar. During this phase, the pressure is carefully regulated to avoid damaging the product. The supply of compressed air or additional low-pressure steam ensures the integrity of the packaging, such as film packaging.

Leadership through quality and flexibility

Our THERMICjet® offers users impressive flexibility. The systems and services are tailored to different products and production sizes in order to guarantee the best possible results. In addition, energy-efficient process management not only delivers savings, but also ensures sustainable operation. Thanks to the integrated automatic cleaning system with optional interior cleaning, the highest hygiene standards are maintained and the cleaning effort for staff is significantly reduced. These properties ensure that the THERMICjet® represents a real competitive edge for your production processes.

THERMICjet® variants

The THERMICjet® is available in two main versions: as a hot smoke cooking system (HR) and as a pure cooking system (KA). Both versions impress with their precise control, high energy efficiency and precisely repeatable processes. The system concept and the production solution guarantee the highest standards of hygiene.

Tailored to your production requirements

Thanks to its design and optional extensions, such as a baking unit or cooling register, the THERMICjet® adapts perfectly to individual production requirements. With a choice of door systems - from the standard up-and-over door to the lifting door - the system is a versatile solution for trade and industry.

Customised product and process solutions

Customer reports

More customer reports